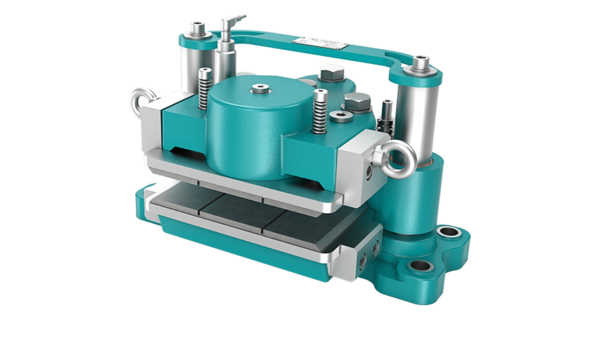

FAB-1-90-100

Floating active brake

- Self-aligning system

- Replaceable brake pads, without loosening mounting bolts

- Spring retracted brake pads

- Applicable for several disc thicknesses

- Air gap brake pads according to customer specification

- Grooved brake pads for redirecting fine dust & contamination

- Drain ports for oil leakage, preventing pads contamination

- Brake open and pad wear switches

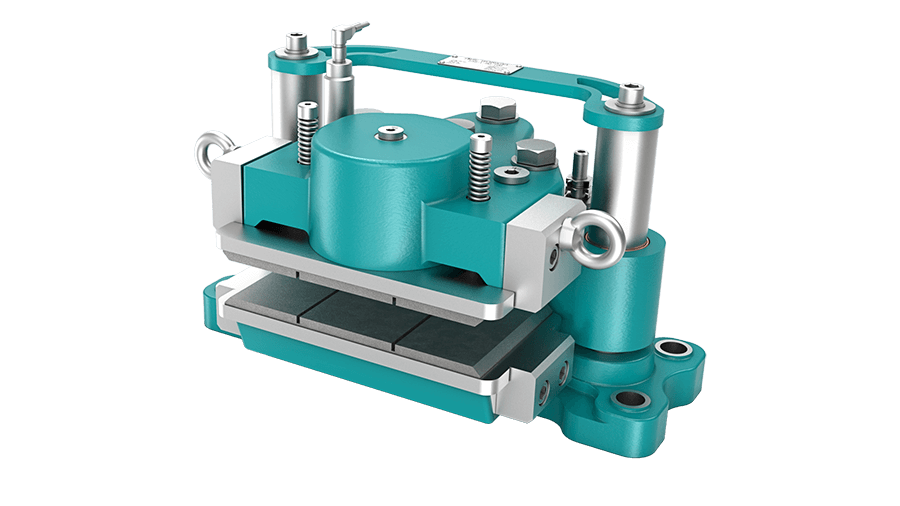

Floating active brakes

Floating active rotor brakes are part of the aerodynamic braking system of the rotor of wind turbines. Floating active rotor brakes are hydraulic applied and spring released, meaning that a brake operation starts when hydraulic pressure is applied to the active brake half. When the brake lining of the active part comes in contact with the disk, the complete floating active rotor brake will slide over 2 shafts, until the opposite brake lining comes in contact with the disc and the braking force will increase to the set pressure value of the hydraulic power unit.

The spring system will cause the floating active rotor brake to remove itself from the brake disc back to neutral position, when the turbine is in operation. The floating active rotor brake will be without hydraulic pressure in such an event.

Floating active rotor brakes are used as an emergency brake and as a service brake for positioning the rotor disc to apply rotor lock devices for mechanical locking during maintenance.